Approach

The approach taken here is to apply the concepts of unit-testing and refactoring to the design of control systems. For electronics, to unit test, one way would be to start with code, then replace it with a piece of hardware that does the same thing, for example, a filter. Refactoring might be recreating a completed project on a breadboard with a duplicate set of parts (to test) and then modifying (to refactor). Good examples are changing the output of a filter, voltage regulator or amplifier, or switching MCU.

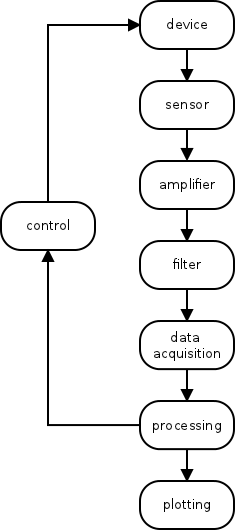

Any control system needs a number of components.

Always start by building the simplest possible device that works. For digital electronics, this is usually a blink program. For a control system, it would be processing a fake signal. While this seems trivial, it validates the whole toolchain: the power supply, the compiler, the programmer, the hardware, the wiring etc. Once that works, make one change at a time and test. If it fails, you know exactly where the problem is! In this way, you can build towards your goal.

Tools of production

Start with a goal and a budget. Buy the best set of equipment you can afford for the project.

Time spent refining your process is never wasted. These are the tools I have to date:

For PIC MCUs:

- XC8 for compiling

- a PicStart+ clone for programming pic16 MCUs (ZIF socket and ISCP) and a PicKit2 clone for programming pic16 and pic18 MCUs (ISCP only)

- pk2cmd for uploading

For AVR MCUs:

- avr-gcc and avr-objcopy for compiling

- a USBasp clone for programming

- AVRdude for uploading

GNU Make for managing compilation and writing of hex files.

For circuit design:

- Eagle with Adafruit library for drawing circuits

For circuit building:

- Power supply

- Fluke 179 DMM

- Hakko FX888D soldering iron

- Panavise 396 with Quadhands workbench mount

- SS-02 solder sucker with silicone tip

- Sidecutters

- Tweezers

- A 2mm drill bit

- A set of electronics screwdrivers

- Wire strippers

- Components: solder, a resistor pack, capacitors, wires, stripboard, breadboards and dev boards

How to choose the next project

There are many projects and limited time. Use the following guide (in order of priority):

- Prefer projects that build on previous projects

- Prefer new projects that enable multiple future projects

- Prefer projects that assist your career

- Prefer projects of commercial application

Some ideas:

- electronic magic 8 ball

- dead reckoning with a rotary encoder and accelerometer

- control the position of one servo motor with another

- motion tracker

- PIC programmer with ICSP